Check out what it's like to work with Micron! Learn More

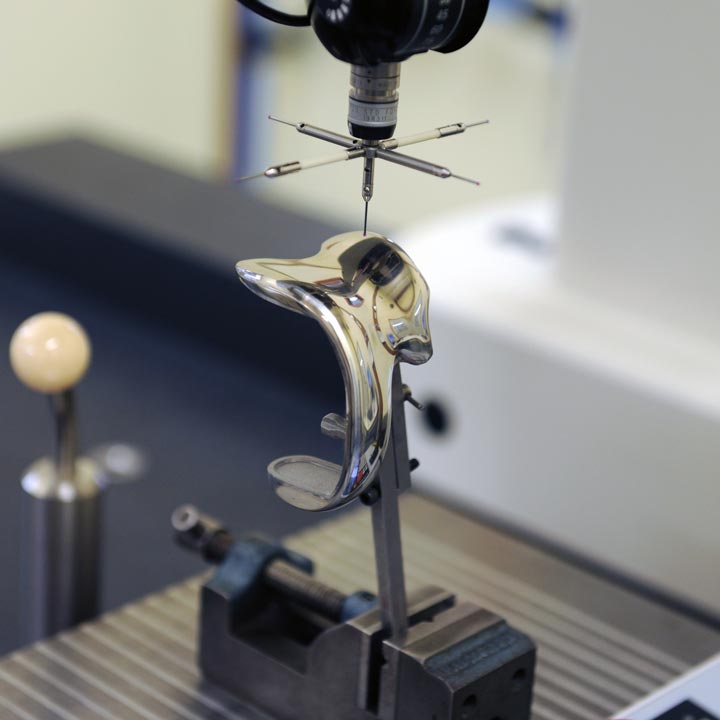

Precision Machining

Micron Solutions has many years of experience machining complex components to the tightest tolerances for medical implants and mission critical defense applications. We have a full array of machining services available, including CNC milling, Mill/Turning and EDM.