Quality Management for Orthopedic Implants

Orthopedic implants interface with the human body and require stringent processes to ensure quality and compliance. As a leading supplier to medical device companies and orthopedic implant OEMs, Micron integrates quality control throughout its entire production process, achieving the highest levels of quality and consistency in the manufacturing of orthopedic implants. Whether working with an innovation start-up or an established medical OEM, quality management systems are co-developed with customers, with Micron’s engineering team supporting our manufacturing capabilities with process development and validation procedures under the guidelines of ISO 13485. From materials verification to operational validation, and final inspection, each stage of the process is rigorously documented and quality-checked in accordance with customer specifications and FDA requirements.

- ISO 13485 Compliant, FDA Registered cGMP, and Custom Quality Management Systems

- IQ/OQ/PQ Validation, Materials Verification; Operational/Design Verification, Operating Scenario Stress Testing

- Class 7, 8, and 10 Clean Room Manufacturing

- Micro Engraving, Barcoding, Laser Marking, and Traceability Features

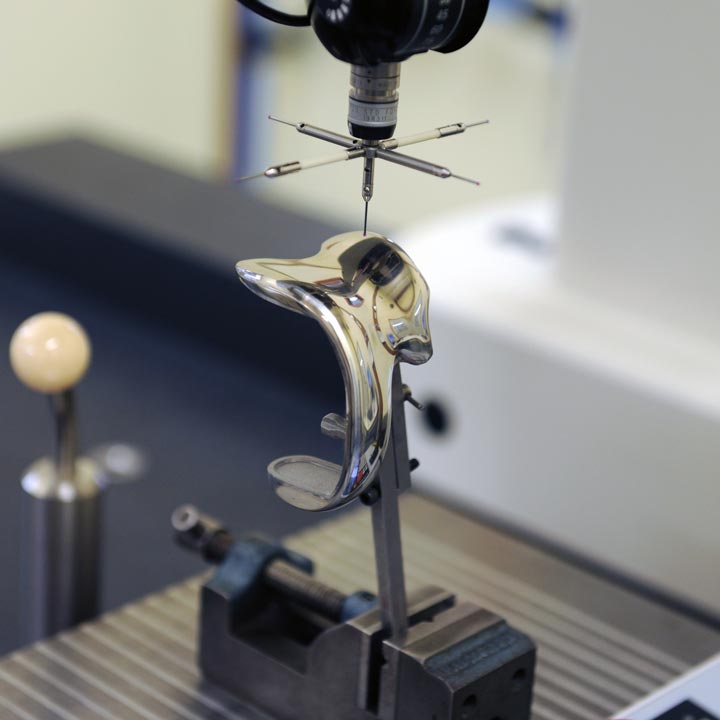

- Coordinate Measuring Machine (CMM), eCad & Vision Inspection

- Ultrasonic Cleaning, Citric/Nitric Passivation and Sterilization