experience that matters

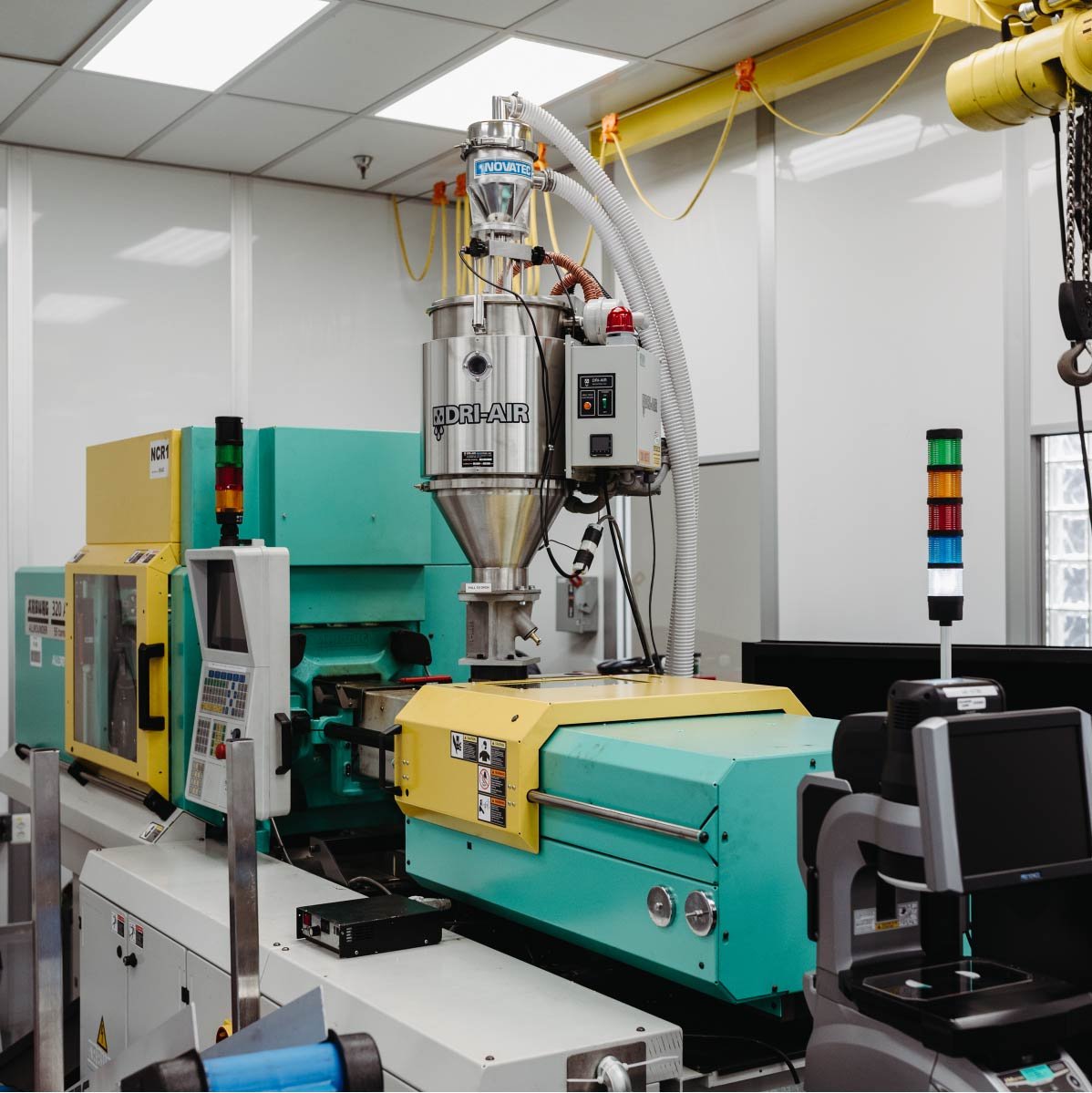

At Micron, no project is too difficult. We have years of experience running high volume projects across a varying degree of part sizes. We have a long, successful history of running projects involving multi shot, insert molding, and over molding using a wide variety of methods such as rotary platen, rotary core, robotic transfer, and manual transfer.

Our engineers have extensive experience running stack molds, valve gate projects, and high cavitation tools with tight tolerances. When applicable, our engineers look to implement in mold pressure and temperature sensing, optical inspection and automation to give our customers the highest quality products at the lowest costs.